Discover top-notch NDT Test in Pune! Ensure quality and safety with our expert non-destructive testing solutions. Get a quote today and safeguard your projects!

An introduction to non-destructive testing

Non-destructive testing (NDT) may be a strategy for recognizing and assessing imperfections in materials. NDT is utilized broadly in air ship plan, fabricate, and maintenance.

The least complex and most exact way to test materials and components is to annihilate them. Dangerous testing is commonly utilized in aviation to decide the physical properties of materials, components, and congregations. It can give profitable data approximately fabric properties such as ductility, tensile strength, and break toughness.

However, dangerous testing isn’t continuously conceivable or alluring when testing aircraft-specific parts and materials, owing to their tall esteem. Instead, engineers and professionals utilize non-destructive testing procedures, gear, and investigation to look at materials and components some time recently and amid benefit, without wrecking them. NDT can moreover distinguish imperfections and contrasts in materials that would something else be troublesome to detect through destructive methods.

What is NDT Test in Pune?

Non-destructive testing (NDT) may be a method of deciding the properties of a fabric, component, or framework without causing harm. It may be a basic instrument in various businesses, counting aviation, car, development, and fabricating.

NDT is commonly utilized to identify imperfections in materials and components, such as breaks, voids, incorporations, and porosity. This strategy can too be utilized to degree fabric thickness, metal hardness, and composite properties.

NDT Examination in Pune: Overview

A collection of assessment procedures known as non-destructive testing (NDT) is utilized to evaluate the qualities, keenness, and characteristics of materials, parts, or structures without causing any hurt. Numerous diverse businesses, counting fabricating, control era, oil and gas, development, and aviation, utilize NDT extensively.

What is the importance of NDT testing?

Not harming Testing is an basic device for ensuring the quality and security of frameworks and items. From breaks and other blemishes to fabricating issues, it can be utilized to test for a wide extend of conceivable issues. NDT Test in Pune can offer assistance avoid costly repairs or substitutions afterward on by recognizing these issues early.

For materials and products to be safe and of high quality, NDT is crucial. It can be applied to:

- Find flaws

- Determine the material’s strength.

- Check component dimensions.

- Verify that the products fulfill the necessary requirements for quality control.

What distinguishes destructive testing from non-destructive testing?

The quality and astuteness of materials are surveyed utilizing two essential testing strategies: damaging testing and non-destructive testing. Materials can be tried without causing any harm much appreciated to non-destructive testing, while damaging testing includes harming the fabric to test its limits.

Every variety has unique benefits and drawbacks. In spite of the fact that it can as it were be connected to a little number of materials, damaging testing is habitually more precise than non-destructive testing. In spite of the fact that non-destructive testing yields less exact comes about, it can be connected to a more prominent assortment of materials.

A number of factors, such as the kind of fabric being tried and the level of precision required, will decide which kind of testing is best for your needs.

Which are the primary NDT method types?

A wide range of non-destructive testing procedures are accessible. Since each of these strategies can be connected to distinguish different sorts of blemishes, it is significant to choose the foremost suitableone for the errand. The foremost popular NDT strategies include:

1. Visual Examination

NDT’s most fundamental and well known strategy is visual testing. To discover conceivable zones of concern, it is as often as possible utilized as the beginning step within the NDT method. In arrange to discover imperfections like splits, scratches, or other inconsistencies, the material’s surface must be outwardly reviewed. In any case, it is compelled by the inspector’s capacity to distinguish the flaw.

2. Examination of Radiography

In radiographic testing, X-rays or gamma beams are utilized to puncture the material’s surface and deliver an picture of the inner structure. Deformity investigation can at that point be performed on this picture. Finding inner harm that’s not clear from the exterior can be finished with radiographic testing.

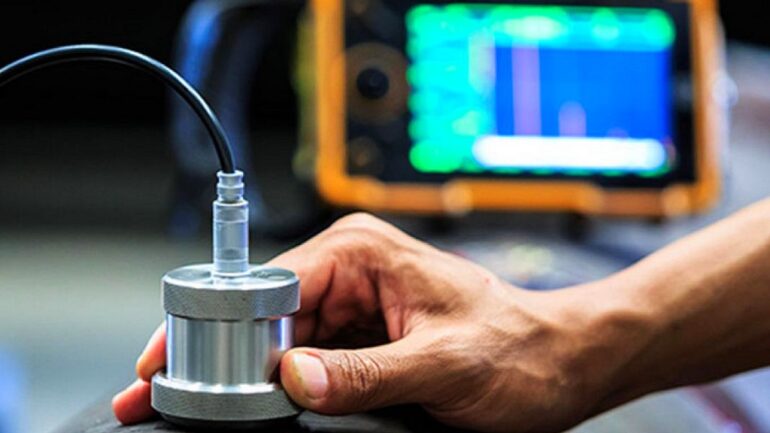

3. Ultrasonic Examination

Using high-frequency sound waves, ultrasonic testing finds fabric imperfections. The sound waves are transmitted into the material, where they will reflect off of any imperfections. After that, an picture that can be inspected for flaws is made from the echoes. Abandons that are outside or inside can be found with ultrasonic testing.

4. Testing of Magnetic Particles

Magnetic Particle Assessment (MPI), another title for Attractive Molecule Testing, may be a strategy that uses magnetic areas to discover surface and subsurface imperfections in ferromagnetic materials. To draw consideration to any absconds within the item, an electrical current is utilized to magnetize press particles, which are at that point connected to the fabric in a attractive field. Attractive molecule testing can be utilized to discover signs, spills, voids, or cracks.

Make Your Own Checklist for NDT

Reduce manual labor and optimize your commerce processes. Considerations Made When Performing Non-Destructive Testing To ensure accurate and compact comes about, a number of components are taken under consideration earlier to performing NDT. The following are these factors:

- investigating the best NDT technique for the item

- Acquiring the necessary specifications for dependable and safe operation

- Procedure characteristics, such as the caliber of the materials used

- The practicality of the existing techniques

- Cost-effectiveness of the planned testing

Conclusion

NDT Test in Pune ensures safety, quality, and reliability in industries like manufacturing, aerospace, and infrastructure. Because of its sophisticated methods for identifying defects without causing harm, it is essential for preserving structural integrity and increasing operational effectiveness in Pune’s industrial environment.